Product Name: Prepainted Galvanized Steel Coil/PPGI

Prepainted Galvalume Steel Coil/PPGL

Product Type:Hot Dip galvanized, Galvalume, Zinc Alloy, Cold Rolled Steel, Aluminum.

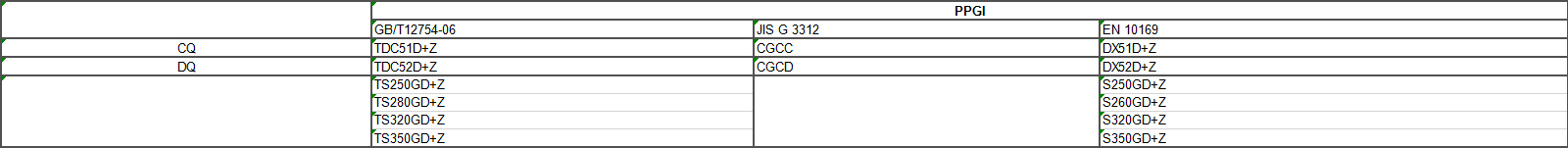

Product Standard: EN, DIN, JIS, ASTM

Grade: DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z

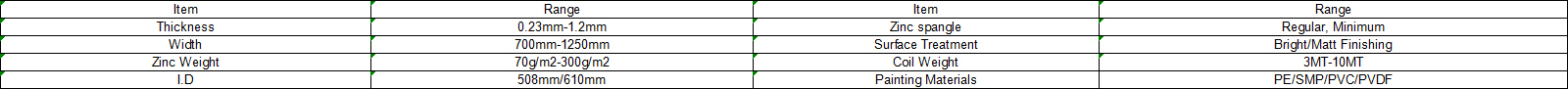

Product Thickness: 0.12-6.0mm.

Width: 600mm-1500mm

Zinc Coating: 20-275g/m2, or customized as required

Base steel: Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel

Surface color: RAL series, wood grain, stone grain, matte grain, camouflage grain, marble grain, flower grain, nano, etc

Coating structure: PE, SMP, HDP, PVDF

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Product Introduction

PPGI & PPGL (prepainted galvanized steel & prepainted galvalume steel) also known as pre-coated steel or color coated steel coil, It is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro galvanized steel sheet, etc. After surface pretreatment, one or several layers of organic coating are applied on the surface, and then baked and solidified. The color coated steel coil is light in weight, beautiful in appearance, and has good anti-corrosion performance, and can be directly processed. The color is generally divided into gray, sea blue, brick red, etc. It is mainly used in advertising, construction, decoration, home appliances, electrical appliances, Furniture industry and transportation industry. The coatings used for color coated steel coils are based on the environment in which the resin is selected, such as polyester silicon modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride, and the like.

Coating Type of PPGI & PPGL

1.Polyester (PE): Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, and low cost.

2.Silicon modified polyester(SMP): Good abrasion resistance and heat resistance, as well as good external durability and chalking resistance, gloss retention, general flexibility, and medium cost.

3.High Durability Polyester(HDP): Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

4.Polyvinylidene Fluoride(PVDF): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, stain resistance, limited color, and high cost.

Main Features of PPGI & PPGL

1.Resistance to acid rain:

Coating protection mechanism: It is very easy to form acid rain in the high level of industrial emissions or pollutants environment. Coating protection mechanism in the surface of pre-painted steel can prevent the steel from acidic penetration, decelerate the corrosion, blistering, peeling and so on.

2.Resistance ultraviolet rays:

Coating protecting mechanism: pre-painted sheet in ultraviolet or strong sunlight conditions, the coating will exhibit chalking degeneration, manifested as discoloration and loss of gloss, lose paint quickly.

3.Resistance to humid heat:

Coating protecting mechanism: in hot and humid environments, high osmotic pressure of water vapor accelerates penetration, forming the degeneration of painting film, then the corrosion of the substrate, with the phenomenon of bubbles and peeling.

4.Resistance to low temperature:

Coating protecting mechanisms: most of the paint can keep stable processing performance above 0 degree, but at alpine region, the temperature will be below 20-40 degree, normal paint will become brittle, bend cracking, or even lose paint, thus protection function is lost totally.

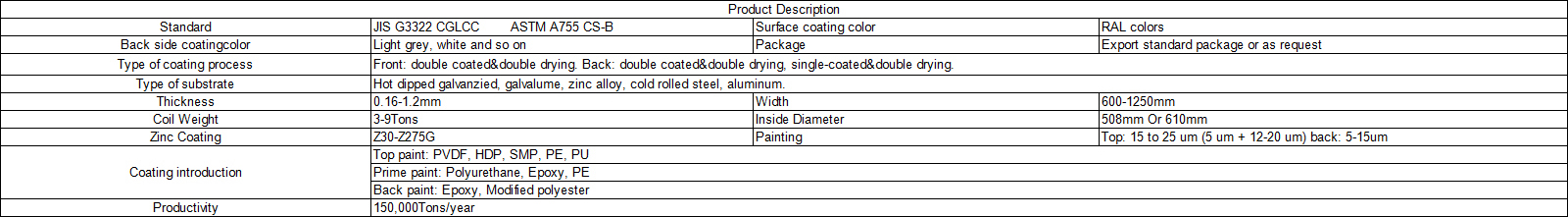

Product Description of Prepainted Galvanized Steel Coil

The steel sheet gets its name because of the organic paint in various colors coated on it. For short, it is called “color-coated steel” or “Pre-Painted Steel”.

For color coating, hot dip galvanized steel strip is used as base material. Color coating can also be done on various other base materials such as galvalume cold rolled steel, stainless steel and aluminum

In addition to the protection provided by zinc coating, The organic paint on top of zinc plays a role in covering and preventing the strip from rusting and make its service life longer than that of galvanized strip by 1.5 times.

The color-coated strip has the advantage of being light in weight, pleasant looking and excellent anti-corrosive properties and can be directly used without any further processing. It’s mainly used in building/ construction industry. It also finds its usage in domestic appliance industry, furniture industry and automotive applications.

The paint used for the color-coated strip is selected depending on different application and environments to which the finished product is likely to be exposed. Commonly used paint systems are Regular Modified Polyester (RMP) Silicon Modified Polyester (SMP), PVC, plastisol and PVDF. User can make choice of any of above paint systems in accordance with their requirements.

INDUSTRY SERVED Available Base Metal

Construction Cold-Rolled Steel Sheet

HVAC Galvanized Steel Sheet

Pipe and Tube Galvalume Steel Sheet

AVAILABLE PAINT TYPES AVAILABLE PAINT BRANDS

Regular Polyester Rainbow Duracoat

Silicon Modified Polyester (SMP) Akzo KCC

High-density Polyester (HDP/ Ceramic Pigmented Paint) Valspar Nippon

BASF Berger

Basic Substrate: Cold rolled HDG / Galvalume

Quality: CQ DQ

Color Standard: Acc to Ral Color Standard or customer's color sample

Standard:

Applications:

1. Outdoor: roof, roof structure, surface sheet of balcony, frame of window, door, garage doors, roller shutter door, booth, Persian blinds, cabana, refrigerated wagon and so on.

2. Indoor: door, isolators, frame of door, light steel structure of house, sliding door, folding screen, ceiling, internal decoration of toilet and elevator.