Pipe Type: Seamless Pipe, Seamless Carbon Steel Pipe, Carbon Steel Seamless Pipe

Application: For Fluids Transmission (oil,gas,water,steam etc.)

Specification:Outer diameter: 13.72-914.4mm

Wall thickness: 1.25-50mm

LENGTH: 5.8/6/11.8/12m

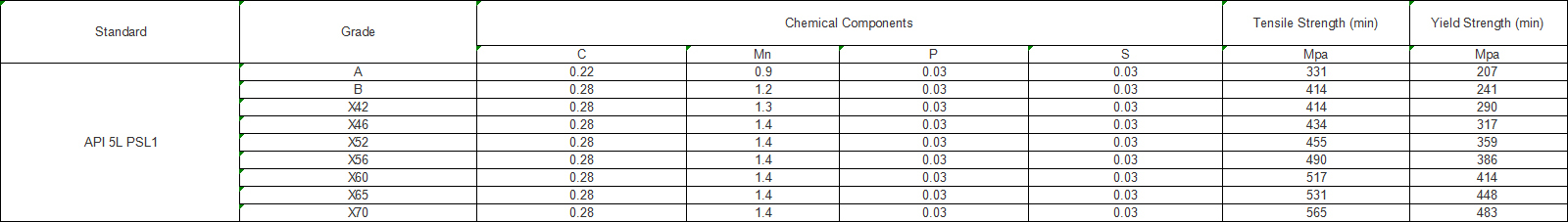

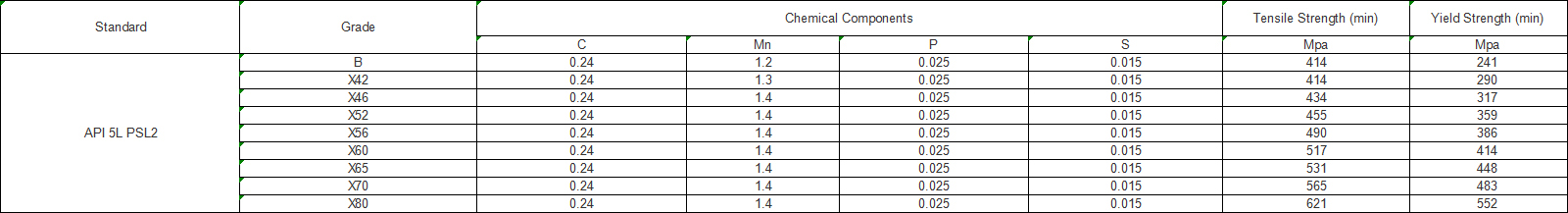

Standard & Grade: API 5L:Gr.A,Gr.B, X42,X46,X52,X56,X60,X65 PSL1 and PSL2

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface:Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Packing: Bundled,Plastic Caps Plugged,Waterproof Paper/Bag Wrapped

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Description

Line pipe is a tube made of high strength carbon steel. It is typically manufactured according to the API 5L metallurgical specification developed by the American Petroleum Institute (API). The raw material can be either seamless or welded carbon steel or stainless steel piping. This product can be used to build pipelines that transport a variety of resources including natural gas, oil, petroleum, and water. API 5L line pipe is available in various diameters ranging from two inches to 48 inches. Its size and diameter required for a pipeline vary according to the amount of gas or liquid that it intended to carry and the pressures it must withstand.

Advantages

1. API 5L line pipes are capable of withstanding high pressures. We conduct many important tests to ensure that it meets the requirements on strength, toughness, and dimensional characteristics.

2. Our products that meet API 5L standards can ensure safe and reliable pipeline service.

3. We purchase tubing materials from Tianjin Pipe Corporation, Baosteel Group, Tianda Group and other famous factories. We only use qualified raw materials for producing line pipes and the production process is supervised by our quality inspectors.

4. We have seven production lines running at the same time in order to ensure short delivery cycle.

Notice

1.Inferior API 5L line pipes tend to get fold lines. This flaw would exist in the hole pipe lengthways. With this flaw, the product would crack when being bended.

2. Inferior products often have pitted surface. This flaw is caused by seriously abraded groove.

3. There would be scab on the surface of inferior pipes. One reason is that the quality of tubing materials is not uniform and there are impurities in them. This flaw is also caused by the crude guide and guard devices of the inferior factories.

4. Inferior line pipe’s surface is easy to get crackles for its blank is adobe. Adobe has many air pores and it will get crackles in cooling process. 5. Inferior pipes are easy to be scuffed. That might be caused by the crude equipment of the inferior factories.

6. Inferior products have no metallic luster. They are in light red or pig iron like color instead.

7. Transverse bars of inferior products are thin. That might because the rolling reduction is too large in the steps before finishing the products.

8. The cross section of inferior line pipe is oval, for the factories set too large rolling reduction in order to save materials.

9. Superior products have uniform composition. Their end faces are smooth and neat.

10. Inferior products have more impurities and lower steel density. The dimensions exceed tolerance limit. 11. Inside dimension of inferior line pipe fluctuates a lot.

12. Superior tubing materials all have normative marks and prints on them.

13. The space between two marks on the pipe should be more than 1m.

14. Longitudinal bars of inferior pipes are always wave-shaped.

15. The factories that produce inferior API 5L line pipes have no cranes. Therefore the packages are loose.