Pipe Type: ERW Pipe,ERW Steel Pipe,Electric Resistance Welding Pipe

Application: Oil/Gas/Water transmission,Machinery Manufacturing

Specification: Outer diameter:21.3mm-660mm

Wall thickness: 1.0mm-20mm

LENGTH:5.8/6/11.8/12 meters

Standard & Grade:API 5L Gr.A,Gr.B,X42,X46,X52,X56,X60,X65 PSL1 and PSL2; ASTM A53, Gr.A,Gr.B

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface:Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Packing: Bundled,Plastic Caps Plugged,Waterproof Paper/Bag Wrapped

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Electric Resistance Welded Pipe

ERW (Electrical Resistance Welding) pipes are manufactured by cold forming of steel coil into a round cylindrical shape are used in various engineering purposes.

ERW steel pipe is formed by rolling plate and welding the seam.

While manufacturing ERW steel pipes, only high-quality, continuous-cast, fully killed, control-rolled, fine-grain, low-carbon steel is used.

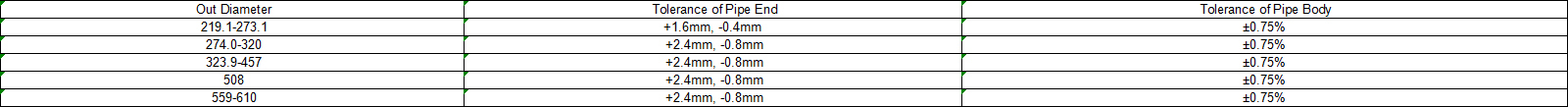

Tolerance of outside diameter

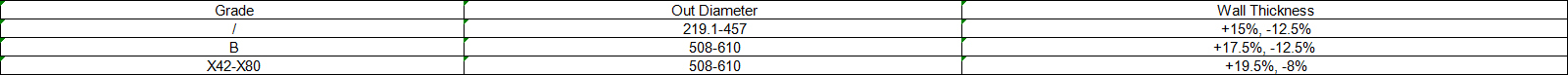

Tolerance of wall thickness

ERW Pipe coating

The surface condition of steel pipe is known as the environment that this is through the steel pipe coating with the surrounding soil insulation, pipe surface condition is different from the four weeks the soil.

Advantage of ERW pipe

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Electric resistance welded

Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material. Initially this manufacturing process used low frequency A.C. current to heat the edges. This low frequency process was used from the 1920’s until 1970. In 1970, the low frequency process was superseded by a high frequency ERW process which produced a higher quality weld.

Difference between ERW, SSAW, LSAW

Steel pipe for pipe technology, can be divided into (SML), mainly as the Oilfield internal transportation pipeline and small-diameter high-pressure natural gas pipeline, used for a small number of long-distance gas pipeline, the vast majority of long-distance pipeline with Direct seam high frequency (ERW), spiral submerged arc (SSAW), LSAW three (LSAW).

a. ERW pipe technical requirements

ERW steel pipes and tubes are used in various engineering purposes, fencing, scaffolding, line pipes etc.

b. Manual ultrasonic testing of ERW steel pipe welding joint

The residual defects in erw steel pipe ultrasonic testing is an important reason for failure of the weld, causing defects missed is inappropriate due to a probe parameter selection, disturbing wave effects and burr flaw echo echo does not distinguish between such a variety of factors.

c. Manual ultrasonic testing of ERW steel pipe welding joint

The residual defects in erw steel pipe ultrasonic testing is an important reason for failure of the weld, causing defects missed is inappropriate due to a probe parameter selection, disturbing wave effects and burr flaw echo echo does not distinguish between such a variety of factors.

d. ERW pipe weld contour shape

Scrape the inside welds very smooth burr, weld and base metal transition very smooth. Usually a steel pipe wall thickness is 11.9mm, a thickness range of extrusion welds typically range from about 25mm to either side of each weld, the weld portion after the removal of burr than other parts of the base material thickness of about 10%.

e. ERW steel pipe products range

ERW steel pipes and tube are available in various qualities, wall thicknesses, and diameters of the finished pipes.

f. ERW pipe welding defects

Analysis of the frequency of inclusions in steel production, the pre-arc fusion inadequate inadequate edge fusion, central fusion deficiencies, stick welding, casting welding, porosity, skip welding and other welding defects nine common causes and preventive measures.

g. ERW pipe issues and defects

ERW pipe issues and defects is related to raw materials, production methods, process conditions, equipment status and personnel. Product defects that appear in the production process by the above factors and constraints.

h. Role of skin effect in erw tubes

Also known as the "skin effect," When an alternating current through a conductor, due to induction effect caused by the larger cross section of the conductor current distribution is uneven, the closer the conductor surface current density.

i. ERW pipe weld surface

High-frequency electric resistance welding (ERW) steel pipe production, internal weld surface treatments are generally incomplete curettage (left weld reinforcement) and complete curettage (scraping will form the inner surface of the groove) in two ways, and the results were not ideal, will affect the overall performance of the steel pipe. Taking into account the thickness of ERW pipe welds, strength and reliability of ultrasonic testing, squeeze through thick welds - calibrating processing, optimized contour shape welds to improve the overall performance of ERW pipe.

g. The welding pressure of erw pipe

Straight seam welded steel pipe, according to welding process can be divided into high frequency resistance welding and submerged arc welding, longitudinal submerged arc welded is short for SAWL, high-frequency straight seam resistance welding is short for ERW.

k. ERW Pipe's development prospects and facing issues

Resistance welding is short of ERW steel pipe with number of advantages, such as high productivity, low cost, good dimensional accuracy, beautiful appearance. However, in the past, due to the poor reliability of the weld, great limitations on the use. The proportion of small pipe production.