Product Type: Galvanized Steel Coils/ Sheets/ Strips.

Product Standard: EN, DIN, JIS, ASTM

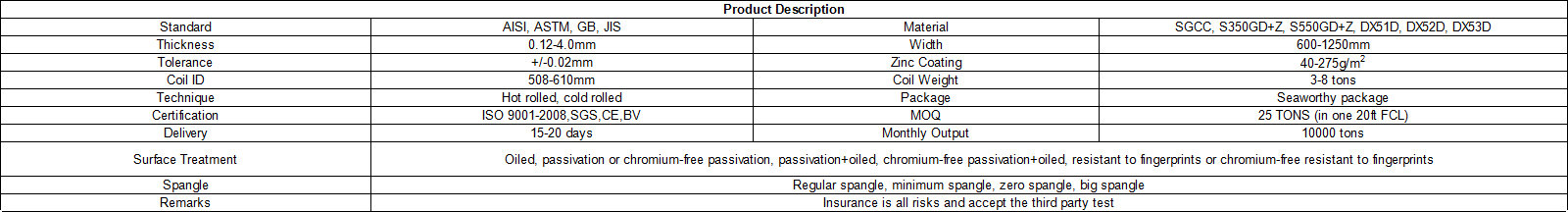

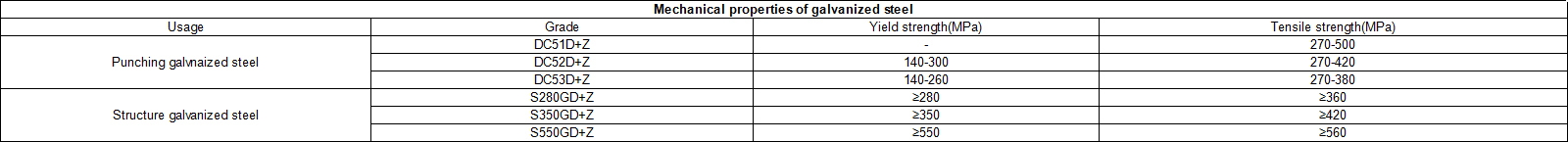

Product Material: Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD , S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80 (550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement

Product Thickness: 0.12mm-6.0mm

Hardness: soft(normal), hard, full hard

Product Description: Zinc Coating: 40-275g/m2

Surface: Normal Spangle; Zero Spangle; Minimum Spangle; Big Spangle.

Hardness: Soft Hard(HRB 60); Medium Hard (HRB60-85); Full Hard (HRB85-95).

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Product Description of Galvanized Steel Coil

Galvanized steel coil products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and other industries. Such as building roofs, highway guardrails, sheet metal processing, roof grilles, household appliance enclosures, ventilation ducts, chimneys, kitchen utensils, grain storage and transportation, frozen processing of meat and aquatic products, etc.

Main Features of Galvanized Steel

Anticorrosive: 13 years in heavy industrial areas, 50 years in the ocean, 104 years in the suburbs and 30 years in cities.

Cheap: The cost of hot-dip galvanizing is lower than that of other coatings.

Reliable: The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

Strong toughness: The galvanized steel sheet layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

Comprehensive protection: Every part of the plated piece can be galvanized, and is fully protected even in depressions,sharp corners,and hidden places.

Save time and energy: Galvanizing process is faster than other coating methods.

Galvanized steel is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce galvanized sheet and coil. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro-galvanizing process consists of the application of zinc by electrolytic disposition. The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer. Our hot-dipped galvanized products are manufacturerd to ASTM A653 specifications while our electrogalvanized products conform to ASTM A879 specifications.

A zinc coating is one of the most effective and economical methods of protecting bare steel from a corroding environment. The zinc not only serves as a barrier between the steel and the environment, it will sacrifice itself to protect the underlying steel sheet. Sacrificial, or galvanic protection occurs when two dissimilar metals are in contact and coupled with water and oxygen. Zinc corrodes preferentially to the iron in steel. This protection prevents corrosion of the steel at areas not covered with zinc. Thus, the spread of corrosion from cut edges, drill holes, etc. is minimized.

Material Types for Galvanized Coil and Sheet Steel

•Commercial Steel (CS Types A, B, and C) •Extra Deep Drawing Steel (EDDS)

•Forming Steel (FS Types A and B) •Structural Steel (SS) – further designated by Grades (33,37,40,50,80)

•Deep Drawing Steel (DDS Types A and C) •High Strength Low Alloy Steel (HSLAS)

In addition, the Hot Dipped Galvanized as well as the Galvannealed products are available in a variety of coating weights including G-90, G-60, G-40, and G-30 for the Hot Dipped Galvanized products, and A-60 and A-40 for the Galvannealed products.

Typical Applications for Galvanized Coil and Steel Sheets:

•Exterior building products •Sashes,

•Ductwork, •Automotive parts,

•HVAC products, •Appliances,

•Flashing, •Commercial and residential steel framing,

•Electrical boxes and other electrical products, •Parking lots

•Roofing, •Truss plates,

•Doors, •Metal building purlins,

•and any other products requiring a corrosion resistant material.

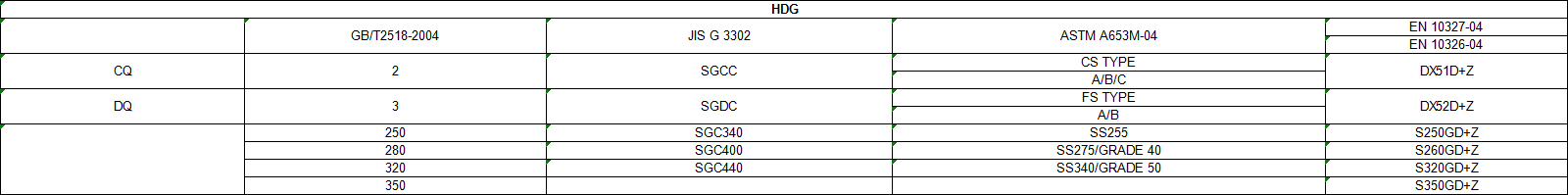

Basic Substrate: Cold Rolled HDG/Galvalume

Quality: CQ DQ

Color Standard: Acc to Ral Color Standard or customer's color sample

Applications: HDG product can be used in automobile, home appliances,medical Instruments, machinery industries, etc.